This method gets the most out of your DeNOx process

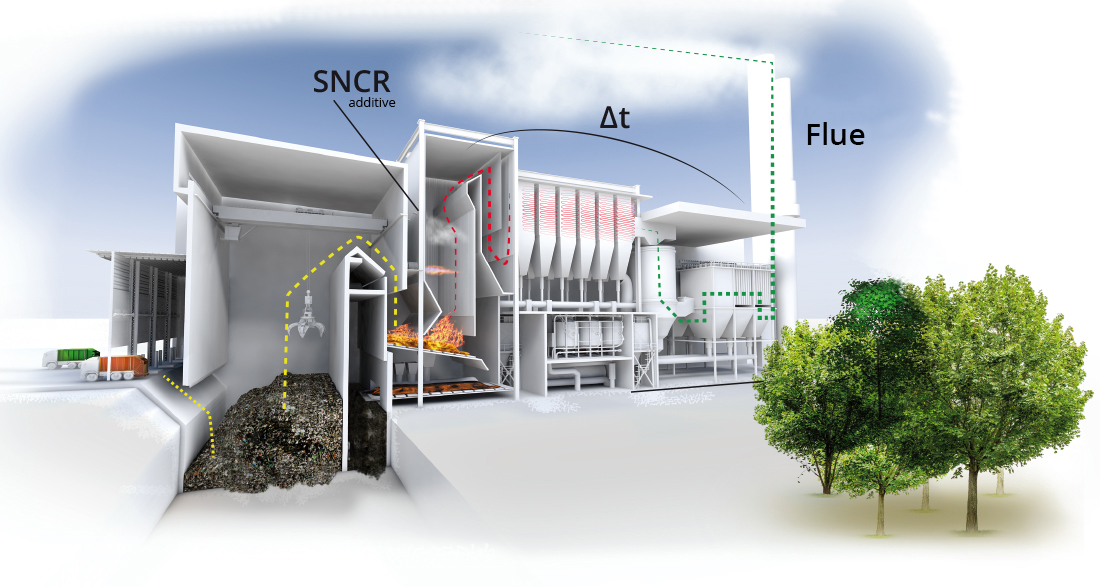

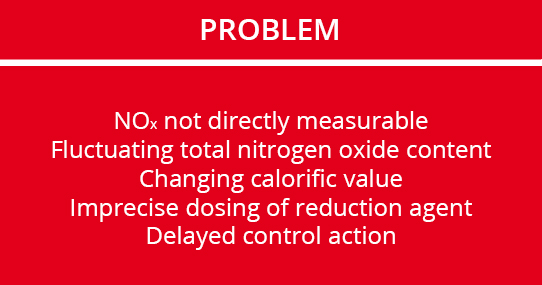

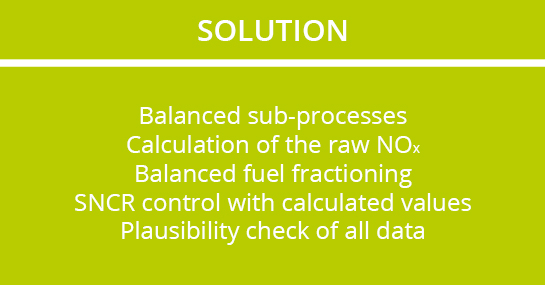

For optimal reduction of nitrogen oxide (NOx) in combustion gases in accordance with the SNCR process the existing NOx quantity must be measured as exactly as possible in order to inject the required amount of reduction agent. In thermal systems, particularly in waste treatment plants, not all combustion parameters can be measured directly. This means that the NOx quantity cannot be measured until the end of the process. Control of the dosing is therefore delayed and imprecise, due to fluctuating parameters. That is why ERC developed Opti-Link – a method that decidedly approaches the ideal of stoichiometric conversion of the reactant.

How you can improve control of your SNCR

The calorific value and the total nitrogen oxide content of the supplied fuel in the thermal waste treatment plant can vary widely depending on their composition. Due to the long travel time for the flue gases to reach the measuring point, dosing of the reduction agent in the SNCR process can be adjusted only with a delay. The result: delayed control, under- or over-dosing of reduction agent, non-stoichiometric conversion.

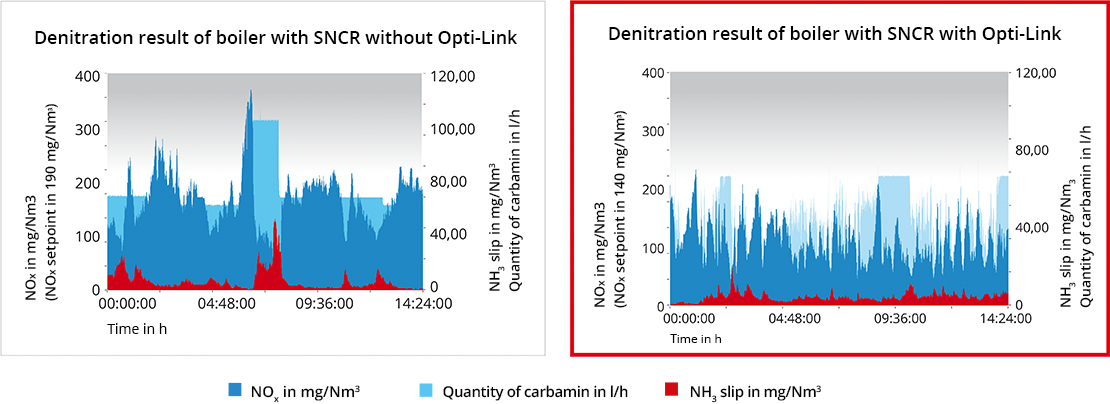

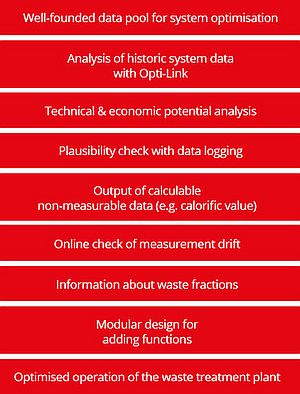

With NOx-Calc, a specific extension of the well-known online balancing method, Opti-Link continuously calculates the total nitrogen content of the supplied waste and balances insufficiently measurable parameters, such as the NOx raw gas value.

For this purpose, the relevant data of all measuring devices is sent via a data interface to Opti-Link through the process control system. Opti-Link balances the entire thermal process by analysing the sub-processes. These sub-processes include the air supply, the fuel supply (to the extent possible), the combustion process, the steam end, the feed water system and the flue gas post-treatment process. The available data is used to create and analyse mass and energy balances, to enable calculation of the values and parameters that cannot be measured directly. They are then immediately available for controlling the SNCR and optimising the overall process.

Consultation, service, optimisation

Service for ERC is more than the sum of single service options. We offer a complete and unique bundle of services covering all aspects of operation and maintenance of industrial combustion and exhaust gas systems. The satisfaction of our customers is always our top priority. We therefore provide you with detailed information on spare parts, maintenance and service for our additive dosing systems, SNCR, SCR and combined systems.

We developed ERC Opti-Link as a method to sustainably improve the performance of your SNCR denitration process. However, the advantages of Opti-Link go far beyond that: on the basis of intelligent processing of the parameters and balancing data of your thermal waste treatment plant Opti-Link enables methods for sustainably optimising your overall process, with the goal of more stable and more economical operation, as well as improved utilisation of the calorific value for the generation of energy. Our experts will be glad to explain the details in person.

To the details ...

our experts are glad to advise you personally.